Silo and Hay Mow Fires on Your Farm

Table of Contents

- Introduction

- The Spontaneous Heating Process

- What is the Cause of Fires?

- Fire Prevention

- Fire Danger Zone?

- Assessment by Probing

- Extinguishment Procedures

- Summary

Introduction

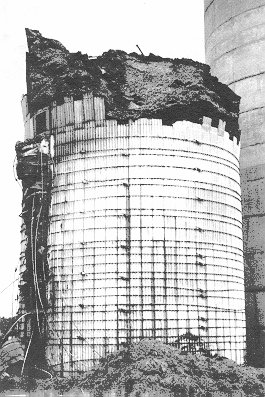

Every year in North America there are fires and feed damage caused by spontaneous combustion and heating. Millions of dollars are lost each year in structures, feed, and cattle from hay and silo fires (see Figure 1). Also LIVES have been lost!

Figure 1. Fire Damaged Stave Silo

The Spontaneous Heating Process

This process of forage heating up and then burning is typically called spontaneous combustion. Spontaneous combustion for hay usually occurs within the first two months of storage. In silos, forage can dry down if air enters the silo through leaks in walls or doors; this results in the potential for fires throughout the whole year.

Spontaneous heating and combustion occurs when sufficient moisture (above 25% and below 45% moisture content for forages), oxygen (air) and organic matter are present together to support the growth of bacteria and molds. This growth results in an initial temperature peak of 54°C to 65°C (130 to 150°F). When the forage reaches this temperature range, a chemical process called the Maillard Reaction may occur, causing additional heat generation. This reaction can be self-sustaining and does not require oxygen (air) to continue. The gases produced will ignite if they have reached a high enough temperature and are exposed to oxygen (air).

What is the Cause of Fires?

- Hay that is too wet will heat (above 25% moisture content) and then enter the spontaneous combustion cycle (see Figure 2 and Table 1).

- Silage and haylage that is too dry will heat (below 40% moisture content) and then enter the spontaneous combustion cycle (See Table 1).

- A large mass of forage which allows the heat to build up.

- A slow trickle of air moving into the material.

- Old silage (2 years) in silo drying down to critical level.

|

Fire Prevention

The moisture of the hay or silage and haylage is the main factor in forage fires. To reduce this burning issue “know the crop moisture content.” Buy a moisture tester or use your microwave oven to determine the moisture content. See Table 2.

Figure 2. Moisture Levels for Hay

Table 1. Recommended Storage Moisture Contents

|

|

Recommended Storage Moisture Content (%) |

|---|---|

| HAY: | |

| Small Square Bales | 15 – 18 |

| Large Round Bales: Soft Core | 13 – 16 |

| Large Round Bales: Hard Core | 12 – 15 |

| Large Square Bales | 12 – 15 |

| SILAGE OR HAYLAGE: | |

| Horizontal Silo | 60 – 70 |

| Conventional Silo | 60 – 65 |

| Oxygen Limiting Silo | 45 – 55 |

| Bagged [Chopped] | 60 – 70 |

| Large Round Bales | 50 – 60 |

| Large Square Bales | 50 – 60 |

Note:

1. Calculated on wet basis

2. Source H. Bellman, S. Clarke, Bob Stone

For hay above recommended moisture levels – a hay dryer should be used. See OMAF Factsheet, Barn Hay Drying, Agdex 120/736, Figure 2 and Table 1. Stack hay on edge to keep bale shape and allow some air flow. Large bales, due to their higher density and greater volume, inhibit dispersal of heat and moisture. Therefore, large bales will burst into flames easier than small square bales if baled too wet. See Table 1 for recommended moisture levels.

The key to fireproofing silos lies in eliminating the combination of dry silage and fresh air. The following components of a silage storage are necessary to make silage and to prevent fires.

A tight silo Check doors regularly and if loose fitting or damaged, repair or air will enter the silage. Air can also enter through damaged silo walls. Empty silo completely every two years. Check walls for damage and repair if necessary. See OMAF Factsheets, Concrete Tower Silo Maintenance and Repair, Agdex 732 and Deterioration of Concrete Tower Silos, Agdex 732.

Moisture content Most silo fires occur because the silage is too dry. Silage should be between 45-65% moisture content. Silage below 40% moisture content, coupled with extra air from poor packing or leakage of air into the silo creates a risk of heat damage or fire.

Length of cut The length of cut should be 10 mm to 6 mm (3/8″ to 1/4″). The short length aids packing (less voids therefore less air) as well as easier unloading.

Distribution Use of a distributor will ensure adequate packing along silo walls and will help limit air movement into the silage from walls and doors.

Filling rate The filling rate should be very rapid for good packing minimum of 1.6 metre per hour (2 feet per hour). This will reduce air trapped in silage and minimize air traveling through silage. Temporary covers can be used if there are long periods of time between fillings.

Fire Danger Zone?

- If mow or silo warms up.

- You see wisps of water vapour (steam).

- If you smell a slight caramel odour.

- Emergency if you have a pungent, scorched stench like burning baler twine. CALL FIRE DEPARTMENT.

- Emergency if you see SMOKE OR FLAMES. CALL FIRE DEPARTMENT.

Assessment by Probing

Hay

When it is evident that hay is heating, the primary goal is to measure the temperature by probing the hay with a homemade device similar to that shown in Figure 3. Probing will determine if you have a fire, and its location or it will assist in assessing the likelihood of a fire. Use the temperature information in Table 3 to help in the decision making. The simplest test is to stick an iron or copper rod deep into the centre of the forage and leave it for about an hour. If it’s almost too hot to hold when removed, you have a problem.

Silage

For silage, temperature readings above 82° C (180° F) indicate that the material will eventually char, smoulder, or burn. Probing silage is mainly used to find the location of the fire, since in most cases a fire is burning before anyone notices the signs of heating. Typically, the fire will be in the top 3 metres (10 feet) or around poorly sealed silo doors. Infrared scanning can also be used to indicate the hot spot location. Access to this equipment may be obtained through your farm safety officer (contact Ontario Ministry of Agriculture and Food office for local officer’s name), the Ontario Fire Marshall’s Office in Toronto, or local insulation companies.

Figure 3. Hay Probe and Thermometer

Table 2. Microwave Oven Method for Determining Moisture Content of Forages

- Weigh out 100 g sample of the chopped forage (W1) excluding the weight of the container. Weigh to the nearest gram.

- Spread the weighed forage sample on a paper plate or place it in a paper bag and put it in the microwave oven.

- Place an 8 oz. glass three-quarters full of water in the oven to prevent igniting the sample or damaging the microwave oven.

- Heat at 80 percent to 90 percent of maximum power for 4 minutes.

- Remove the sample, mix it and weigh it.

- Continue to reheat for 2 minute intervals, re-weighing each time. To prevent burning, use lower heat and 30 second time intervals as it approaches being dry. If the weight of the sample does not change after two or three drying intervals, it is 100 percent dry. This is the final dry weight (W2). A slightly charred sample should not affect accuracy of the moisture determination but if the sample burns the test should be repeated.

- Calculate moisture content as follows:Moisture Content = (W1-W2) ÷ (W1) x 100

Example:W1 = 100 gms

W2 = 36 gmsMoisture Content = (100-36) ÷ (100) x 100 = 64%

| Temperature | Action |

|---|---|

| 88° C (190° F) | Remove hay rapidly to a safe distance away from the barn. While there is evidence that hay may heat to a point several degrees above 200° F (93° C) without ignition, it is best to remove it with help from the local fire department. Remove animals and tools before touching the hay. Better to take precautions than to suffer losses. |

| 82° C (180° F) | Call your fire department and make immediate provision for standby service. Also notify your insurance agent, who will be glad to cooperate and may make arrangements for additional protective service. |

| 80°C (175° F) | Hot spots or pockets may be anticipated at 175° F. Above this temperature, keep all doors and other openings closed to prevent drafts. |

| 77° C (170° F) | You must maintain constant vigilance and take temperatures periodically, looking for possible hot spots. |

| 70° C (160° F) | Time to take notice! If you have an automatic temperature alarm, it will sound at this point giving you sufficient time to make necessary preparations for removing the hay – if you act promptly. |

| 65° C (150° F) | Entering the danger zone! Up to this point, temperatures are not to be considered abnormal, although anything above 125° F (52° C) is unusual. |

Warning

Mows that have heated to a considerable degree are dangerous to walk on – a worker may drop into a burning pocket. If it is necessary to enter the mow, long planks must be used. Help should be on hand in case of an accident.

Information courtesy of Ohio State University Cooperative Extension Service.

Extinguishment Procedures

Hay

For hay storage, heating is often confined to a pocket within the storage. The attempt to remove this pocket should only be done when the fire department is there with a water truck, since the material may flame when exposed to air. Removal of hay may be accomplished by using a High-Hoe or a logging clam. Hay should be placed a good distance away from the barn in case it starts to burn.

If the fire is so active that it must be extinguished in the barn, wet the hay and remove immediately. Workers must be aware of the potential for collapse of bridged hay over fire cavities in the barn.

Extreme caution must be taken when the hay has been treated with chemical preservatives containing ethoxyquin and BHT (butylated hydroxytoluene), since they will produce deadly hydrogen cyanide gas.

Silage

Call the fire department and let them put the fire out. Fire fighters will require full turn out gear including self-contained breathing apparatus due to dangerous silo gases. In conventional open top silos, they will locate the hot spots with a probe and put it out by injecting small streams of water through the probe right to the seat of the fire. Gases may be produced when injecting water into a hot silage fire. However, there is no containment of gases since the silo is open and not sealed which practically precludes the occurrence of an explosion.

In conventional open top silos unloading of fire damaged silage is recommended:

- Since there is very little nutritional value left.

- Water has leached the acids allowing molds to grow and spoil the silage.

- Re-ignition of silage material may occur.

Thorough dousing of the top layers of forage before unloading and running the unloader intermittently will minimize unloading problems due to fire and motor over heating.

In oxygen-limiting silos a fire is potentially very dangerous, since there is containment of explosive gases. The method of control will be to inject liquid nitrogen or carbon dioxide into the silo to cool the fire. See Table 4 for the amounts needed.

Table 4. Estimate Amounts of Carbon Dioxide, or Liquid Nitrogen for Control of Silate Fires

| Silo Size Diameter x Height |

Carbon Dioxide (CO2) |

Liquid Nitrogen (N2) |

|---|---|---|

| 20′ x 60′ | 20 Cylinders | 40 Cylinders |

| 20′ x 70′ | 22 Cylinders | 44 Cylinders |

| 20′ x 80′ | 30 Cylinders | 60 Cylinders |

| 24′ x 60′ | 30 Cylinders | 60 Cylinders |

| 24′ x 70′ | 35 Cylinders | 70 Cylinders |

| 24′ x 80′ | 40 Cylinders | 80 Cylinders |

| 30′ x 60′ | 45 Cylinders | 90 Cylinders |

| 30′ x 70′ | 50 Cylinders | 100 Cylinders |

| 30′ x 80′ | 60 Cylinders | 120 Cylinders |

Note: Gas cylinders are large size

Source: Extinguishing Silo Fires & (NRAES-18) by Dennis J. Murphy and William C. Arble, Pennsylvania State University

Every oxygen-limiting silo should have valves specifically designed to inject gases for fire control. For Harvestor Silos see Operators Manual 1991 Chapter 7 Emergency Procedures. This chapter gives step-by-step instructions on putting out a fire in their silos.

Summary

Silage and hay fires can be safely extinguished by fire departments. If a fire occurs on your farm, call the fire department. They have the equipment and the training to deal with it.

Reviewed By: Robert Stone, P. Eng., Ontario Ministry of Agriculture and Food

Harold House, P. Eng., Ontario Ministry of Agriculture and Food

This Factsheet was authored by: Stephen Clarke, OMAF, Kemptville, ON

For more information…contact Stephen Clarke at steve.clarke@omaf.gov.on.ca